Recycling Targets Can’t Be Solved with Yesterday’s Tools

Recycling Targets Are Rising and Can’t Be Solved with Yesterday’s Tools

Waste processing today is shaped by accelerating regulations, circular economy mandates, and growing public demand for cleaner outcomes. But while volumes increase and materials become more complex, many facilities still rely on outdated, single-purpose sorting systems, dramatically escalating these problems:

- Glass entangled in compostable waste

- Non-ferrous metals mixed with inert materials

- Plastics containing flame retardants or dark pigments

- E-waste streams with unpredictable internal structures

Without intelligent automation, these problems escalate — driving up costs, reducing material recovery, and making compliance harder to achieve.

| • Low sorting precision | • High contamination levels |

| • Manual rework and labor dependence | • Missed recovery value in every load |

What if your sorting system could learn, adapt, and evolve — just like the waste it processes?

Know more from linevsystems.com

From Vision to Separation: Adaptive Intelligence for Complex Waste Streams

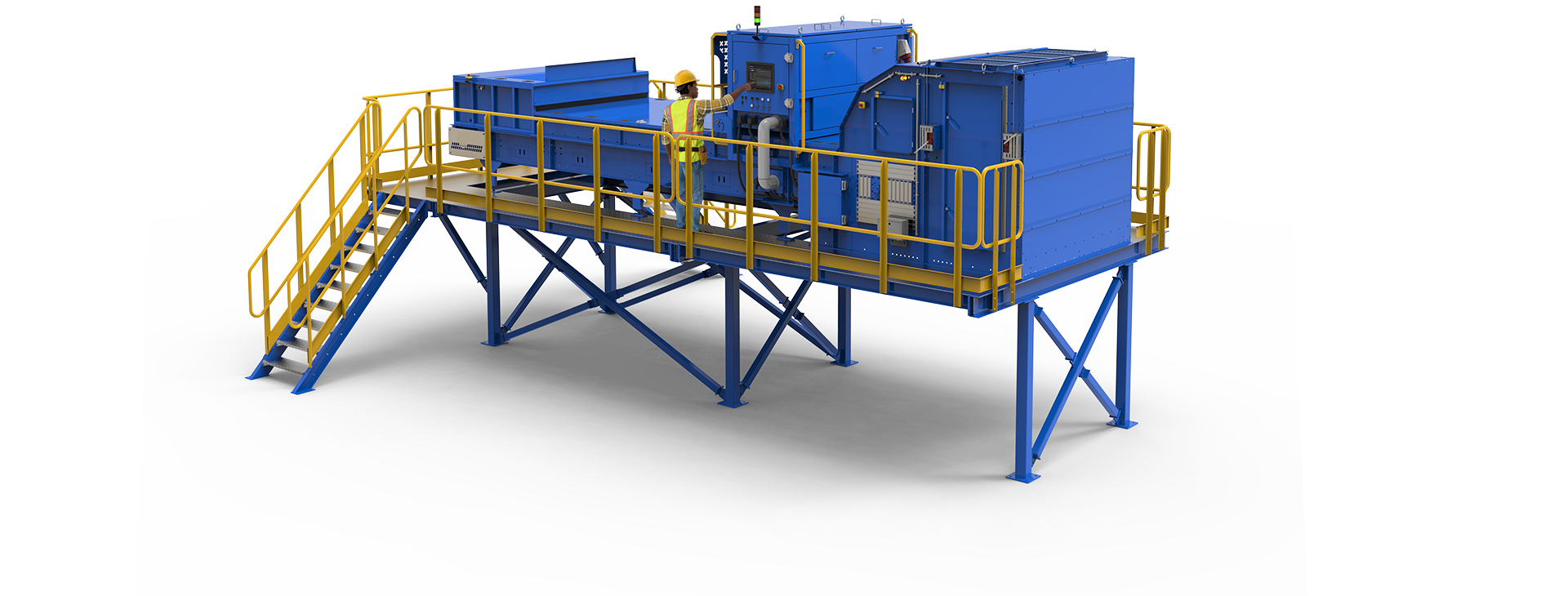

X-SORT is an advanced AI-powered X-ray sorting system designed to recover value from complex waste — quickly, accurately, and continuously.

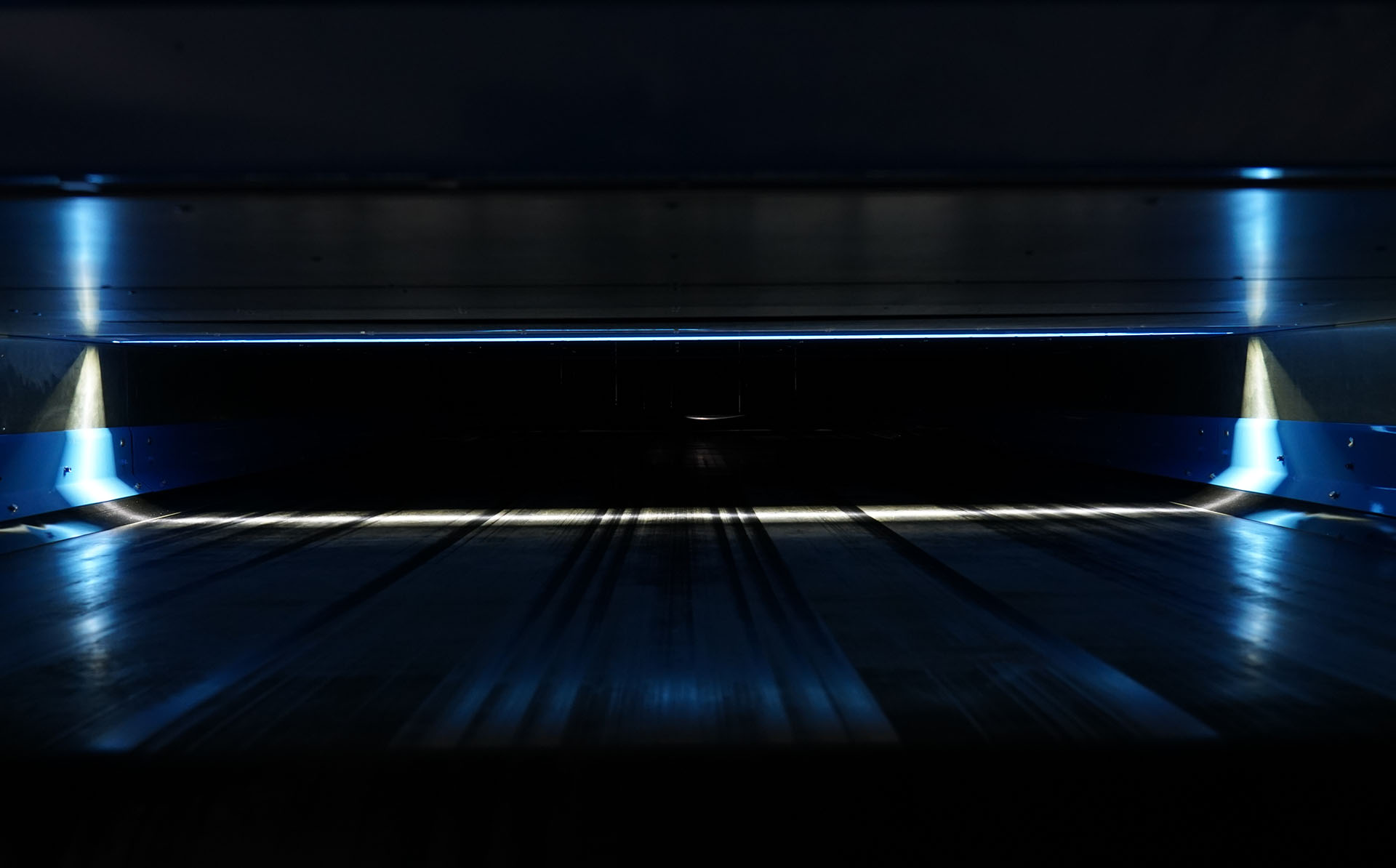

At its core is a combination of dual-energy X-ray transmission (DEXRT), optical RGB detection, and deep neural vision algorithms. This hybrid approach enables the system to not only see inside waste — but understand what it’s made of, how dense it is, and where its center of mass lies, even for small or contaminated fragments.

X-SORT was originally built for high-throughput glass recovery from municipal solid waste (MSW). It detects and separates glass particles as small as 10×10 mm — even when mixed with organic matter or moisture-heavy compost. But the system was never limited to glass. With its AI-driven architecture and configurable ejection map, X-SORT can be adapted to identify and sort a wide range of materials, including:

- Non-ferrous metals (aluminum, copper alloys)

- Dark-colored or contaminated plastics

- Flame-retardant polymers

- Wood, organic matter, and clean bio fractions

- Electronic waste components (e.g., lithium cells, printed circuits)

X-SORT is not a fixed machine. It’s a platform — ready to grow with your plant, your regulations, and your waste streams. Whether you’re targeting glass, metals, plastics, or just want to reduce landfill loads, X-SORT brings adaptable intelligence to your sorting line.

For facilities struggling with increasing contamination, low recovery rates, or tightening recycling standards — X-SORT provides not just a system, but a scalable, intelligent solution that evolves with your needs.

The system processes a continuous mono-layer of waste at up to 3 meters per second, achieving throughput up to 20 tons per hour. With dual real-time feedback loops — optical calibration and X-ray monitoring — it maintains stable performance across long shifts and variable material quality.

Materials are classified by AI and separated using high-speed pneumatic ejection valves with a response time under 5 milliseconds. Sorting logic is built on trained neural models, which can be updated or replaced depending on customer needs or future materials.

From Glass Sorting to Intelligent Material Separation

X-SORT was initially designed to tackle one of the most complex problems in modern waste management: precise, high-throughput recovery of glass from mixed municipal waste streams — even when glass is embedded in moisture-heavy compost or organic fractions.

But at its core, X-SORT is not just a glass sorter. It’s a modular, AI-powered platform that leverages dual-energy X-ray transmission (DEXRT), optical recognition, and deep neural networks to identify and separate materials based on their atomic density, shape, color, and structure.

This hybrid sensing architecture allows the system to go far beyond the limitations of single-sensor or color-based sorters. Whether you’re processing construction debris, shredded e-waste, or high-variability industrial byproducts, X-SORT can adapt to your material logic.

Multi-Sensor Intelligence for Complex Waste Streams

The system analyzes every object in the waste flow using a combination of synchronized sensors:

- Dual-energy X-ray imaging reveals material density and atomic structure.

- RGB cameras analyze surface features such as color and texture.

- Neural algorithms fuse data in real time to classify materials with high accuracy.

The result is a high-speed, automated decision process — where materials are identified, classified, and separated within milliseconds, even in the presence of dirt, moisture, or mixed contamination.

Unlike traditional sorters, which rely on rigid rules or simple image matching, X-SORT adapts. Models can be trained and re-trained to support new materials, updated legislation, or changes in input waste composition — without hardware changes.

Not Just a System — A Configurable Platform

X-SORT is designed as a scalable solution that fits into existing or new processing lines. From simple two-fraction separation to complex multi-material sorting, the platform offers configurable logic maps and ejection strategies.

This enables facilities to recover more value, reduce landfill output, improve organic purity, and meet even the strictest recycling targets — all with fewer manual interventions and lower operational costs.

The system is equally effective in applications such as:

- Removing small glass shards from compostable streams

- Identifying and rejecting ceramics and stones from glass lines

- Sorting aluminum and copper from crushed metal flows

- Separating dark polymers, multilayer packaging, and fire-resistant plastics

- Pre-sorting electronic scrap to detect embedded batteries or metal inserts

Every facility is different — and X-SORT is built with that in mind. Whether your challenge is regulatory, environmental, or operational, this system evolves with your needs.

Designed for glass. Ready for more.

X-SORT delivers precise separation of glass from organic and inert waste — even in high-humidity or compost-heavy streams.

- E-waste metals

- Plastics with fire retardants

- Aluminum and copper alloys

- Clean organic fractions

3D View

Environmental Compliance

X-SORT is designed for high-performance sorting of mixed solid waste streams, including glass, plastics, metals, and composite materials. The system focuses on identifying and separating material fractions commonly discussed in the context of the Regulation (EU) 2019/1021 on Persistent Organic Pollutants (POPs) and the Stockholm Convention.

These include plastic components, aluminum laminates, coatings, and insulation materials that may contain or be associated with POP-listed substances such as perfluorinated compounds (PFOA, PFOS), UV stabilizers (UV‑328), and flame retardants used in consumer packaging and electronics.

Through the combined use of optical recognition and X-ray imaging, X-SORT enables the targeted separation of these POP-relevant materials at an early stage of waste processing. This approach supports cleaner input streams for downstream recycling, reduces the risk of unintentional environmental release, and contributes to the responsible management of complex waste containing potentially regulated substances.

Key features

Built for Complexity

X-SORT is designed to operate where conventional systems fail — in waste streams that are wet, mixed, contaminated, or unpredictable. It handles real-world complexity without compromising performance.

Powered by AI, Not Rules

Unlike traditional rule-based sorting systems, X-SORT uses neural networks trained on real materials to classify each fragment based on structure, density, and image signature — adapting continuously to material variability.

Dual-Sensor Intelligence

The system combines dual-energy X-ray transmission with RGB optical imaging to deliver a deeper, multidimensional understanding of every object. It sees both inside and across the surface — and makes decisions in milliseconds.

Adaptable to New Materials and Regulations

X-SORT is a platform, not a fixed-function device. New materials, recovery goals, or regulatory targets can be addressed by updating AI models and sorting logic — without changing hardware.

High Throughput Without Compromise

Capable of processing up to 20 tons per hour, X-SORT maintains accuracy even at high belt speeds. Smart ejection control ensures minimal loss and maximum recovery — without slowing down operations.

Adaptable, Scalable, Future-Ready

X-SORT is engineered as a universal, AI-driven solution that scales with your operation. Whether integrated into a dedicated glass recovery line or part of a larger MSW sorting facility, it adapts to changing waste profiles, compliance needs, and recovery strategies — without reconfiguration or hardware modification.

Built for Complexity

X-SORT is designed to operate where conventional systems fail — in waste streams that are wet, mixed, contaminated, or unpredictable. It handles real-world complexity without compromising performance.

Powered by AI, Not Rules

Unlike traditional rule-based sorting systems, X-SORT uses neural networks trained on real materials to classify each fragment based on structure, density, and image signature — adapting continuously to material variability.

Dual-Sensor Intelligence

The system combines dual-energy X-ray transmission with RGB optical imaging to deliver a deeper, multidimensional understanding of every object. It sees both inside and across the surface — and makes decisions in milliseconds.

Adaptable to New Materials and Regulations

X-SORT is a platform, not a fixed-function device. New materials, recovery goals, or regulatory targets can be addressed by updating AI models and sorting logic — without changing hardware.

High Throughput Without Compromise

Capable of processing up to 20 tons per hour, X-SORT maintains accuracy even at high belt speeds. Smart ejection control ensures minimal loss and maximum recovery — without slowing down operations.

Adaptable, Scalable, Future-Ready

X-SORT is engineered as a universal, AI-driven solution that scales with your operation. Whether integrated into a dedicated glass recovery line or part of a larger MSW sorting facility, it adapts to changing waste profiles, compliance needs, and recovery strategies — without reconfiguration or hardware modification.

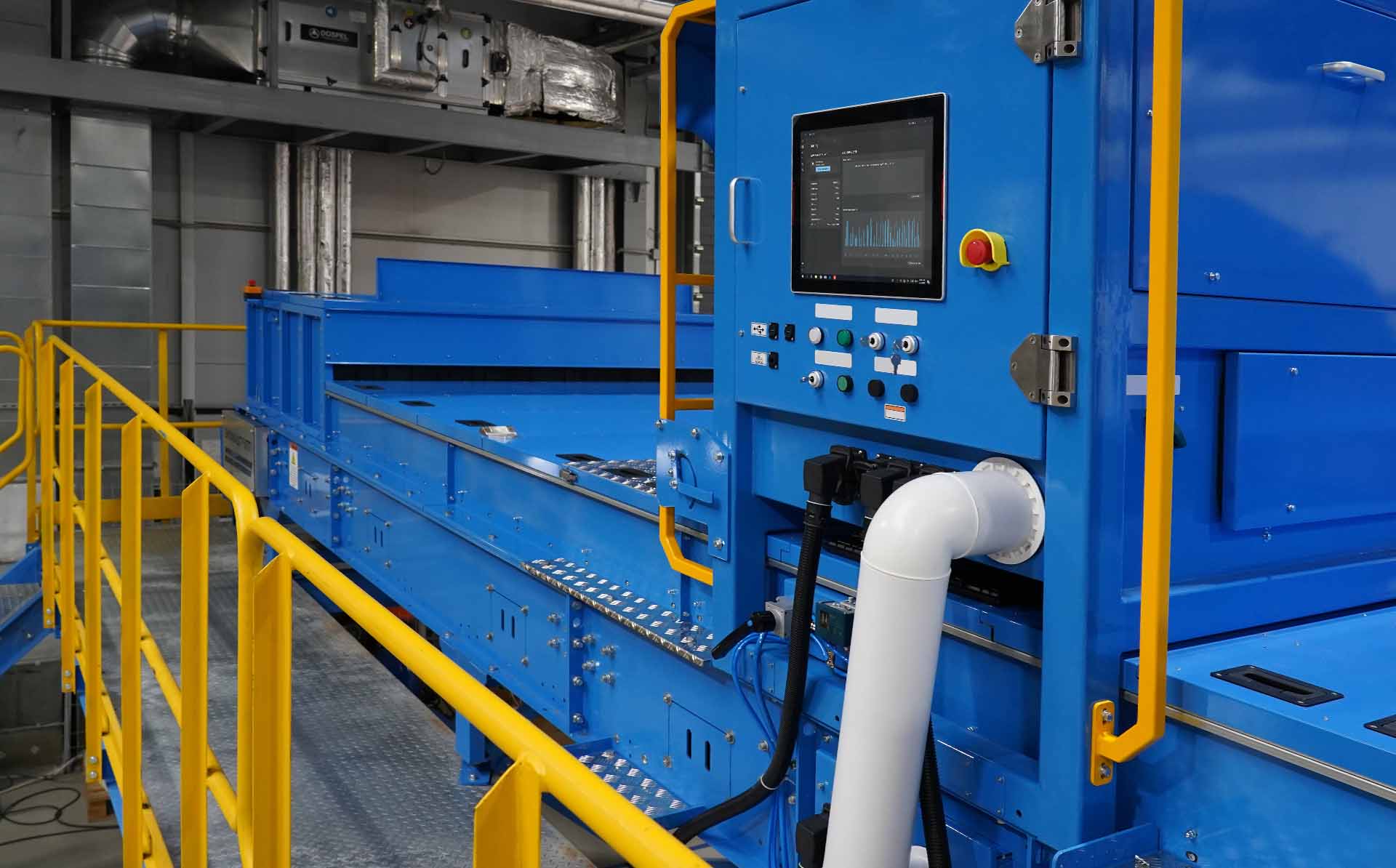

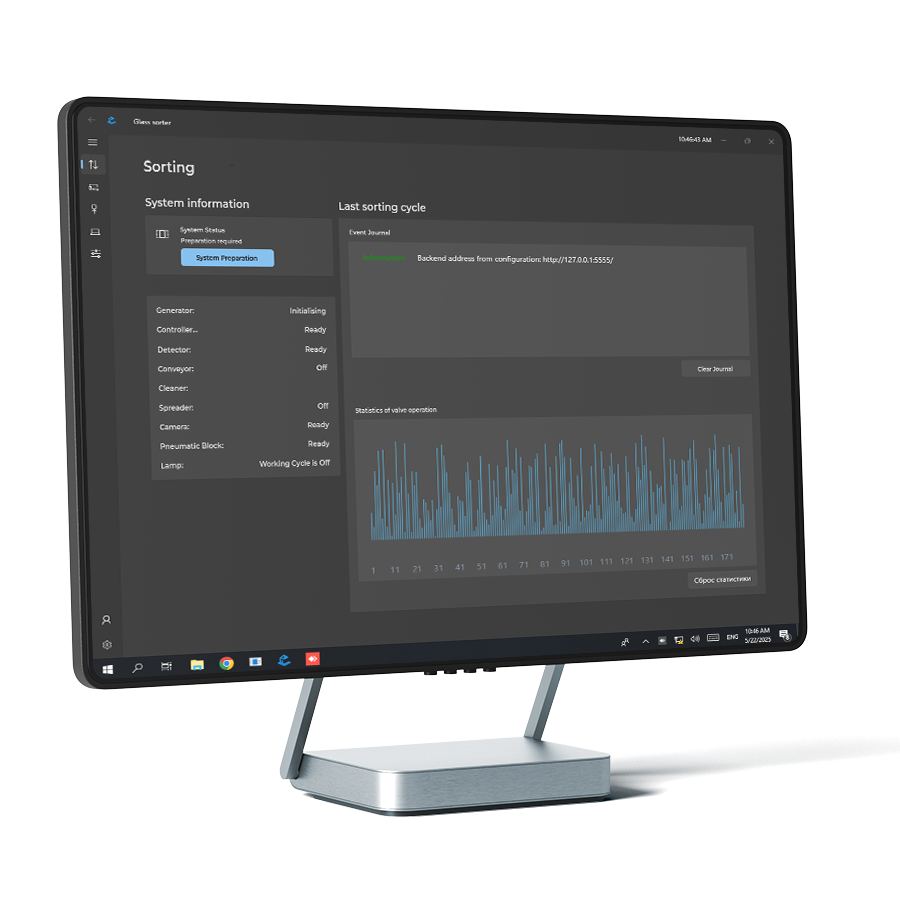

Smarter Sorting Starts with Smarter Software

X-SORT is driven by an intelligent software core that fuses sensor data, controls system logic, and enables continuous adaptation to evolving waste streams. Far beyond a simple interface, this software orchestrates the full classification and ejection process — in real time and at industrial scale.

At the heart of the platform is a neural inference engine that processes synchronized input from dual-energy X-ray and optical RGB cameras. This data fusion allows the system to detect, classify, and map materials across the conveyor — triggering high-speed pneumatic ejection with millisecond precision.

The system continuously calibrates itself through embedded sensors, monitors detection performance, and logs operational metrics for process optimization. Trained AI models can be updated or extended for new materials, compliance requirements, or custom recovery scenarios.

Real-Time AI Classification

| Custom Logic and Ejection Mapping

|

Self-Calibration and Monitoring

| Data Logging and Performance Analytics

|

With its adaptive architecture, the software platform makes X-SORT uniquely capable of evolving with your process. Whether the challenge is regulatory compliance, new material streams, or process optimization — the system’s intelligence is built to scale and adapt.

Built-in sensors monitor system performance, adjusting for belt load, material density, and environmental conditions — ensuring stability without manual recalibration.

From light organics to dense mineral fragments, the system maintains classification and ejection precision even at peak throughput — enabling industrial-scale efficiency without quality trade-offs.

No mechanical separation or brushes inside the scanning zone — just air and data. This design reduces mechanical wear and avoids cross-contamination, especially in organic waste lines.

Technical data

Technical Details

| Sorting throughput | Up to 20 tons/hour |

| Conveyor speed | Up to 3 m/s |

| Minimum object size | 10 × 10 mm (≥2 mm height) |

| Glass detection efficiency | ≥ 85% |

| Cross-contamination | ≤ 5% |

| Max object weight | Up to 1 kg |

| Operating time | ≥ 20 hours/day |

| Power supply | 3-phase, 400 V, 50/60 Hz, 22.5 kVA |

| Pneumatic system | 8 bar, ISO 8573-1:2010 Class 5:3:3 |

Dimensions

| Overall dimensions | |

|---|---|

| Length | 9250 mm |

| Width | 8120 mm |

| Height | 4500 mm |

| Weight (approx.) | ~ 6,500 kg |

|---|

Technical Details

| Sorting throughput | Up to 44,000 lbs/hour |

| Conveyor speed | Up to 9.84 ft/s |

| Minimum object size | 0.39 × 0.39 in (≥0.08 in height) |

| Glass detection efficiency | ≥ 85% |

| Cross-contamination | ≤ 5% |

| Max object weight | Up to 2.2 lbs |

| Operating time | ≥ 20 hours/day |

| Power supply | 3-phase, 400 V, 50/60 Hz, 22.5 kVA |

| Pneumatic system | 116 psi, ISO 8573-1:2010 Class 5:3:3 |

Dimensions

| Overall dimensions | |

|---|---|

| Length | 30.35 ft |

| Width | 26.63 ft |

| Height | 14.76 ft |

| Weight (approx.) | ~ 14,330 lbs |

|---|

Product Videos

Learn more

At the Core of X-SORT: Physics, Intelligence, and Precision

X-SORT is built around a core physical principle: materials interact with X-rays differently depending on their atomic structure. By using dual-energy X-ray transmission (DEXRT), the system captures energy-dependent attenuation patterns that allow it to differentiate materials not just by color or surface — but by what they’re made of. This enables confident separation of glass, metals, plastics, and composites, even when visually identical or covered in dirt or moisture.

Where most systems stop at detection, X-SORT goes further. Each object is analyzed using a real-time neural inference engine that fuses radiographic and optical data. This fusion delivers contextual classification — meaning the system understands not only what it sees, but also how to act on it. It identifies, maps, and assigns objects to target categories with precision, even in challenging environments like compost-laden MSW or e-waste with layered materials.

This scientific foundation is wrapped in a flexible software platform that adapts the system to your needs. New materials? New compliance goals? X-SORT evolves without retooling — by simply updating its detection logic. The result: reliable, automated, and measurable performance across materials and industries.

The fastest way to hear back from us is to fill the contact form below. One of our expert team will get back to you as soon as possible.